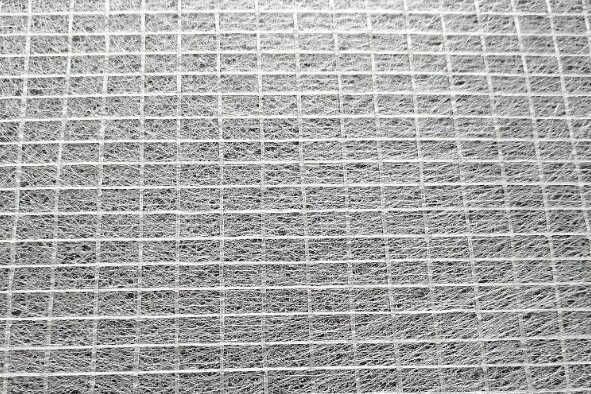

Glass fiber tissue, also known as fiberglass mat or glass fiber mat, is a non-woven material made from randomly oriented glass fibers bonded together with a resin binder. It's commonly used in various applications where strength, durability, and resistance to heat and chemicals are required. Here's a basic overview of how glass fiber tissue is made and where it's commonly used:

Manufacturing Process:

-

Glass Fiber Production: The process starts with the production of glass fibers. This involves melting raw materials, typically silica sand, limestone, and soda ash, in a furnace at high temperatures to form molten glass. The molten glass is then extruded through tiny openings to form continuous filaments.

-

Formation of Mat: The continuous glass filaments are collected on a conveyor belt or a rotating drum to form a loosely arranged mat. This mat may consist of randomly oriented fibers.

-

Binder Application: A resin binder is applied to the mat to hold the fibers together and provide structural integrity. The binder can be applied in various ways, such as spraying, dipping, or saturating the mat.

-

Curing: The mat with the resin binder is then passed through an oven or subjected to heat to cure the resin. This process solidifies the binder, forming a cohesive structure.

-

Finishing: After curing, the glass fiber tissue may undergo additional processing steps such as cutting to size, coating with additives for specific properties, or surface treatments for improved adhesion.

Applications:

-

Composite Manufacturing: Glass fiber tissue is commonly used as a reinforcement material in composite manufacturing processes. It is often combined with resin matrices such as polyester, epoxy, or vinyl ester to produce fiberglass composites used in industries like aerospace, automotive, marine, and construction.

-

Insulation: Glass fiber tissue is used as insulation material in buildings, appliances, and industrial equipment due to its excellent thermal insulation properties.

-

Soundproofing: It's also used for soundproofing applications in buildings, vehicles, and industrial machinery.

-

Reinforcement in Plastics: Glass fiber tissue can be added to plastic products to improve their strength, stiffness, and dimensional stability. This is common in the production of automotive parts, sporting goods, and consumer products.

-

Electrical Insulation: In electrical applications, glass fiber tissue is used as insulation material in cables, circuit boards, and electrical equipment due to its electrical insulation properties.

-

Corrosion Resistance: Glass fiber tissue is resistant to many chemicals, making it suitable for applications where corrosion resistance is required, such as in chemical processing equipment and storage tanks.

Overall, glass fiber tissue is a versatile material with a wide range of applications across various industries where its unique properties provide significant benefits.