Reinforcement Materials Provided by EAS Fiberglass

EAS Fiberglass offers a wide range of fiberglass products designed for various applications, including FRP (thermoplastic and thermoset plastic), cement, bitumen, mica reinforcement, and lamination of FRP composites. Here is an overview of the materials and their applications:

Types of Glass Fibers

-

E Glass: Widely used for general-purpose applications. It provides good strength and is cost-effective. Commonly used in:

- PCB (Printed Circuit Boards): Due to its fire resistance and electrical insulation properties.

- Mica Tape Products: For similar reasons as PCB usage.

-

ECR Glass: Known for its enhanced chemical resistance, making it suitable for environments exposed to corrosive substances.

-

S Glass: Offers higher strength and modulus compared to E glass, making it suitable for high-performance applications such as aerospace and military.

-

C Glass: Primarily used for its chemical stability and is often found in applications requiring resistance to corrosion.

-

AR Glass (Alkali-Resistant Glass): Designed to resist alkali attack, making it suitable for use in cement and concrete reinforcement.

Fiberglass Forms

-

Direct Roving: Continuous strands of fiber used for filament winding, pultrusion, and gun spray-up molding. Treated with Silane S510 for optimal performance.

-

Assembled Roving: Bundled fibers are used in similar applications as direct roving but are treated with Silane S710 for enhanced properties in gun roving.

-

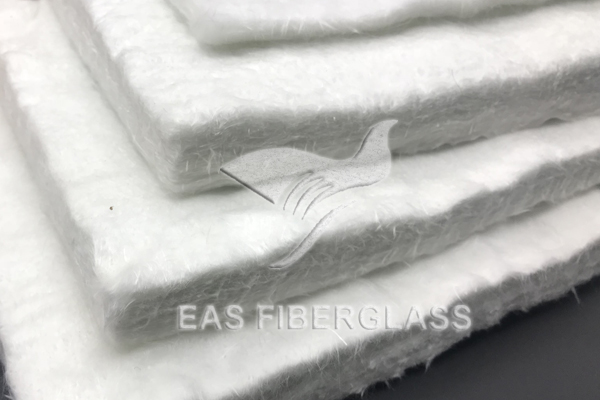

Chopped Strands Mat: A non-woven fabric made of randomly distributed chopped strands. It's commonly used for laminations due to its ease of handling and conformability.

-

Woven Roving: Made by weaving continuous roving strands, providing high tensile strength. It is widely used in lamination processes for various FRP applications.

-

Glass Fabric: High-strength fabric used in marine and entertainment composite constructions. It combines lightweight and high-strength properties.

-

Glass Mesh Scrim Fabric: Exhibits good corrosion resistance and is used in construction materials like wall stucco, gypsum, cement boards, and bitumen.

Properties of Different Glass Types

| Property | S Glass | E Glass | ECR Glass | C Glass | AR Glass |

| Density (g/cm³) | 2.54 | 2.58 | 2.72 | 2.52 | 2.70 |

| Softening Point (°C) | 1056 | 846 | 882 | 750 | 773 |

| Tensile Strength (MPa) at 23°C | 4800 | 3440 | 3600 | 3310 | 3250 |

| at 400°C | 4420 | 2620 | 2150 | 1500 | -- |

| at 550°C | 2410 | 1680 | 1680 | -- | -- |

| Young’s Modulus (GPa) at 23°C | 86.9 | 72.5 | 80.5 | 68.5 | 73.5 |

| at 550°C | 88.9 | 81.5 | 81.5 | -- | -- |

| Elongation (%) | 5.7 | 4.8 | 4.8 | 4.8 | 4.8 |

Finishes

- 276 Finish: A clear finish providing a transparent and aesthetically pleasing appearance while maintaining the material's properties.

Applications

- Marine Industry: Using high-strength glass fabric for lightweight yet durable constructions.

- Construction: Glass mesh scrim fabric for stucco, gypsum, and cement boards.

- Electronics: E glass for PCBs due to its electrical insulation and fire resistance.

- High-Performance Composites: S glass for applications requiring superior strength and modulus.

EAS Fiberglass’s diverse range of products and finishes ensures they can meet specific requirements across various industries, enhancing the durability, strength, and performance of composite materials.

EAS Fiberglass Co., Ltd is a professional fiberglass products supplier and provides comprehensive and effective material industrial solutions covering the market of high-performance FRP, highly effective temperature insulation, and highly convenient construction. Nowadays, EAS owns various product lines of fiberglass yarn forming, woven fabrics, fabric coating/lamination, FRP, etc. The complete product lines enable EAS to master the quality control and products market competitive. Taking this advantage involves us in many projects and enhance brand promotion. Certified ISO9001-2008 equips EAS staff and management with a more professional operation. Certification of test reports for products is made by third-party laboratories SGS, TUV, DNV, etc.