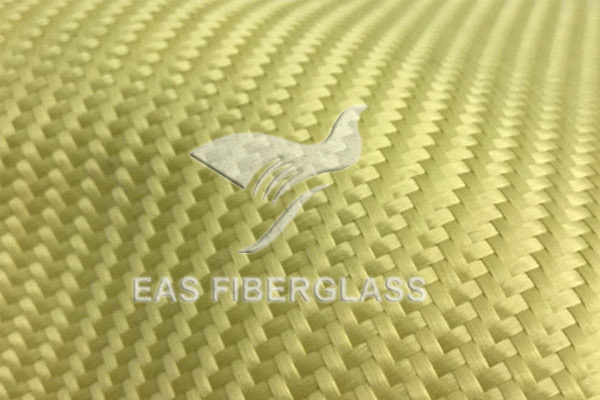

Kevlar, a high-performance synthetic fiber, is renowned for its remarkable strength, heat resistance, and versatility. Developed by chemist Stephanie Kwolek in the 1960s, Kevlar has since become a crucial material in various industries, including defense, automotive, and sports. Here’s a deeper look into Kevlar fabric, including its composition, properties, manufacturing process, and specific applications.

Kevlar is made from a polymer called poly-para-phenylene terephthalamide. This synthetic fiber consists of long molecular chains that are tightly packed, creating a material that is both incredibly strong and lightweight. The unique arrangement of its molecules allows Kevlar to withstand significant stress without breaking.

High Tensile Strength: Kevlar's strength comes from its molecular structure, which allows it to handle high levels of stress and strain. This property is crucial for applications where safety and protection are paramount.

Lightweight: Despite its strength, Kevlar is lightweight, making it suitable for items that need to be worn or used for extended periods without causing fatigue.

Heat and Flame Resistance: Kevlar can withstand temperatures up to about 400°F (204°C) without losing its structural integrity. This heat resistance is vital for industries where exposure to high temperatures is common.

Chemical Resistance: Kevlar is resistant to many chemicals, including oils and solvents, making it useful in various industrial settings.

Low Stretch: Kevlar has minimal stretch, allowing for greater control and precision in applications like ropes and cables.

The production of Kevlar involves several steps:

Polymerization: The starting materials are combined to create a polymer solution.

Spinning: This solution is then spun into fibers. The spinning process can be done through wet or dry spinning methods, where the polymer solution is forced through a spinneret to form continuous fibers.

Drawing: The fibers are stretched to align the molecular chains, enhancing their strength.

Finishing: The fibers undergo various treatments to improve their properties, such as water resistance and UV stability.

Ballistic Armor:

Automotive Industry:

Aerospace:

Sports Equipment:

Industrial Applications:

Kevlar’s exceptional properties and versatility make it an indispensable material in many fields. Its ability to provide safety, durability, and performance continues to revolutionize industries, ensuring that it remains a vital component in the development of advanced protective solutions. If you have any specific areas you want to explore further, let me know!