Basalt Fiber vs. Fiberglass

Basalt Fiber

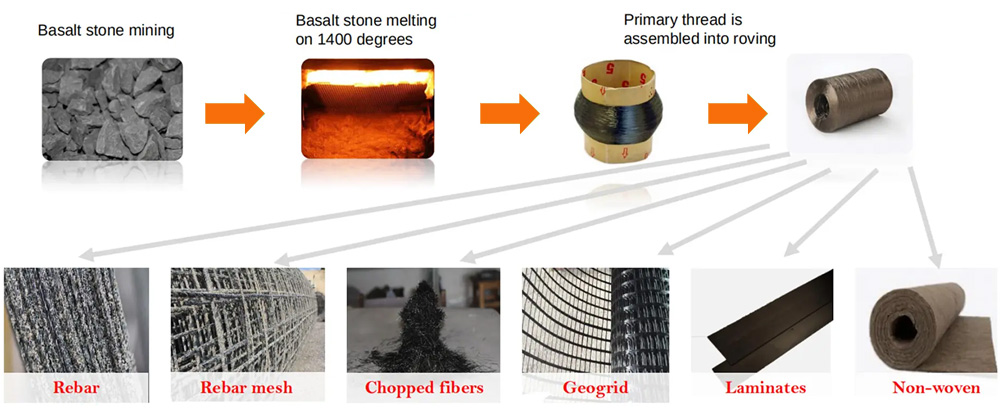

Introduction Basalt fiber is a continuous fiber drawn from natural basalt. Basalt stone is melted at 1450°C to 1500°C and then drawn through a platinum-rhodium alloy wire drawing plate to create continuous fibers. The pure natural basalt fiber is generally brown. It is an environmentally friendly green high-performance fiber composed of oxides such as silica, alumina, calcium oxide, magnesium oxide, iron oxide, and titanium dioxide. Basalt fiber offers high strength and a variety of excellent properties such as electrical insulation, corrosion resistance, and high-temperature resistance. Additionally, the production process produces less waste, causes minimal environmental pollution, and the product can degrade directly in the environment without harm.

Applications Basalt continuous fibers are used in fiber-reinforced composites, friction materials, shipbuilding, heat-insulating materials, the automotive industry, high-temperature filtration fabrics, and protective fields.

Characteristics

- Abundant Raw Materials: Basalt fiber is derived from basalt ore, which is abundant on Earth and even the Moon, making the raw material costs relatively low.

- Environmentally Friendly: Basalt ore is natural and does not release harmful substances during production, making it a green, low-cost, high-performance material.

- High Temperature and Water Resistance: Basalt fiber works well within 269°C to 700°C, with a softening point of 960°C, significantly outperforming glass fiber and carbon fiber at high temperatures.

- Chemical Stability and Corrosion Resistance: Basalt fiber's composition enhances its resistance to chemical corrosion and water, especially in alkaline and acidic environments.

- High Modulus of Elasticity and Tensile Strength: Basalt fiber has an elasticity modulus of 9100-11000 kg/mm² and tensile strength of 3800-4800 MPa, making it a strong reinforcing material.

- Sound Insulation: Basalt fiber has excellent sound absorption, with the absorption coefficient increasing significantly with frequency.

- Dielectric Properties: Basalt fiber has a higher volume resistivity and better dielectric properties than E glass fiber.

- Silicate Compatibility: Basalt fiber disperses well in cement and concrete and has strong bonding and weather resistance.

- Low Moisture Absorption: Basalt fiber's moisture absorption is less than 0.1%, lower than many other fibers.

- Low Thermal Conductivity: Basalt fiber's thermal conductivity is 0.031-0.038 W/m-K, lower than many other fibers.

Fiberglass

Introduction Fiberglass is an inorganic non-metallic material known for its good insulation, heat resistance, corrosion resistance, and high mechanical strength. It is produced by melting raw materials like chlorite, quartz sand, limestone, dolomite, boron calcium stone, and boron magnesium stone, then drawing, winding, and weaving the fibers. Each filament's diameter ranges from a few microns to over 20 microns. Fiberglass is widely used as a reinforcing material in composites, electrical insulation materials, thermal insulation materials, and other areas of the national economy.

Material Properties

- Melting Point: Fiberglass softens between 500°C and 750°C.

- Boiling Point: Approximately 1000°C.

- Density: 2.4-2.76 g/cm³.

- Tensile Strength: 6.3-6.9 g/d in dry conditions and 5.4-5.8 g/d in wet conditions.

- Heat Resistance: Maintains strength up to 300°C.

- Electrical Insulation: Excellent, making it a high-level electrical insulation material.

- Chemical Resistance: Resistant to most chemicals except concentrated alkali, hydrofluoric acid, and concentrated phosphoric acid.

Main Features

- High Tensile Strength: Fiberglass has high tensile strength with low elongation (3%).

- High Elasticity: Provides good rigidity and can absorb large impact energy.

- Non-Combustible: Inorganic fiber that is non-combustible and chemically resistant.

- Low Water Absorption: Absorbs minimal water.

- Stable and Heat Resistant: Exhibits good scale stability and heat resistance.

- Good Processability: Can be made into strands, bundles, felts, fabrics, and other forms.

- Transparent and Light Transmittable: Fiberglass allows light transmission.

- Good Adhesion with Resin: Adheres well to resin.

- Cost-Effective: Inexpensive compared to other fibers.

- Non-Burnable: Can fuse into glassy beads at high temperatures.

Comparison

Raw Materials

- Basalt Fiber: Made from natural basalt ore.

- Fiberglass: Made from a combination of chlorite, quartz sand, limestone, dolomite, boron calcium stone, and boron magnesium stone.

Environmental Impact

- Basalt Fiber: Environmentally friendly, with minimal waste and no harmful emissions.

- Fiberglass: Generally more energy-intensive to produce and may release some emissions.

Temperature Resistance

- Basalt Fiber: Can withstand higher temperatures (up to 700°C) without losing strength.

- Fiberglass: Effective up to 300°C.

Strength and Elasticity

- Basalt Fiber: Higher modulus of elasticity and tensile strength.

- Fiberglass: High tensile strength but lower than basalt fiber.

Chemical Resistance

- Basalt Fiber: Better resistance to chemical corrosion, especially in alkaline environments.

- Fiberglass: Resistant to most chemicals but susceptible to concentrated alkali, hydrofluoric acid, and concentrated phosphoric acid.

Applications

- Basalt Fiber: Used in high-performance applications such as aerospace, automotive, and construction materials.

- Fiberglass: Used broadly in insulation, reinforcement of plastics, and various industrial applications.

Cost

- Basalt Fiber: Generally more expensive due to the specialized production process.

- Fiberglass: More cost-effective and widely used.

Both basalt fiber and fiberglass offer unique advantages and are chosen based on the specific requirements of the application.

EAS Fiberglass Co., Ltd is a professional fiberglass products supplier and provides comprehensive and effective material industrial solutions covering the market of high-performance FRP, highly effective temperature insulation, and highly convenient construction. Nowadays, EAS owns various product lines of fiberglass yarn forming, woven fabrics, fabric coating/lamination, FRP, etc. The complete product lines enable EAS to master the quality control and products market competitive. Taking this advantage involves us in many projects and enhance brand promotion. Certified ISO9001-2008 equips EAS staff and management with a more professional operation. Certification of test reports for products is made by third-party laboratories SGS, TUV, DNV, etc.