What is Hypalon Coated Polyester Fabric?

Overview: Hypalon-coated polyester fabric is a high-performance material that combines the strength and durability of polyester with the protective and resilient properties of Hypalon, a type of Chlorosulphonated Polyethylene (CSPE). This fabric is known for its exceptional resistance to environmental factors, making it ideal for a variety of demanding applications, particularly in marine environments and outdoor settings.

Key Characteristics of Hypalon-Coated Polyester Fabric:

-

Base Material (Polyester):

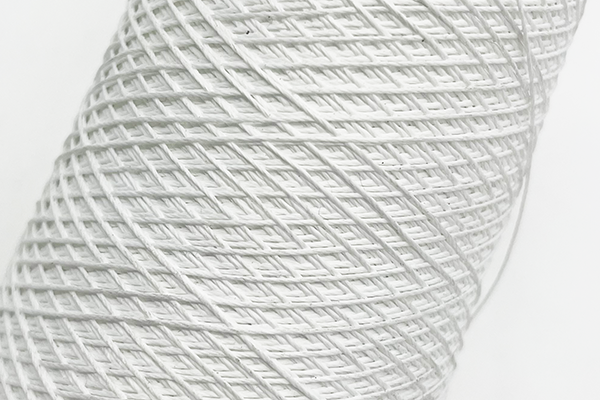

- The base of the fabric is polyester yarn, which offers lightweight and flexible properties.

- Polyester fabric provides excellent shape memory, meaning it can return to its original shape even after stress or deformation.

- Polyester is UV-resistant and has low flammability, adding to its safety and longevity in outdoor use.

-

Hypalon Coating:

- Hypalon is an improved version of chloroprene, known for its superior resistance to chemicals, ozone, and light degradation.

- The coating significantly enhances the fabric’s performance in extreme conditions, including high resistance to weathering, heat aging, and low gas permeability.

- The coated fabric is particularly valued for its excellent resistance to sea environments, including prolonged exposure to saltwater and sunlight, making it the preferred choice for inflatable boats, marine structures, and other applications exposed to harsh outdoor conditions.

-

Durability:

- The fabric's construction with high breaking strength in both warp (longitudinal) and weft (transverse) directions ensures that it can withstand significant mechanical stress without tearing.

- Its elongation properties in both warp and weft allow for flexibility without compromising strength, essential for applications requiring elasticity and durability.

Applications:

- Marine and Inflatable Boats: Hypalon-coated polyester fabric is widely used for inflatable boats and marine structures due to its resistance to saltwater, UV radiation, and weathering. Its low permeability makes it ideal for keeping air or gas in, ensuring the structure remains inflated and intact.

- Protective Structures: Its excellent weathering properties make it a top choice for sun protection systems, such as tarps and sunshades, where exposure to sunlight and heat is a constant challenge.

- Straps and Ropes: The fabric is also used for industrial straps, rope coverings, and other applications requiring flexibility, strength, and resistance to environmental factors.

- Tires and Other Industrial Uses: Its flexibility and durability extend to applications in tires, inflatable shelters, and air containment structures.

Performance Properties:

- High Strength: With warp and weft breaking strengths ranging from 90 daN/5cm to 2000 daN/5cm and 80 daN/5cm to 1400 daN/5cm respectively, the fabric can endure substantial mechanical loads.

- Elongation: The elongation at break ranges from 10% to 20%, offering both flexibility and the ability to absorb shock or stress without tearing.

- Weather and Temperature Resistance:

- The fabric can withstand continuous temperatures ranging from -40℃ to 120℃ and point temperatures up to 130℃ without losing its mechanical properties.

- This wide temperature range makes it suitable for applications in extreme climates or high-heat environments.

Technical Specifications:

- Weight per square meter: From 450 g/m², making it a relatively lightweight material while maintaining its strength and durability.

- Fabric Thickness: Thickness can be customized upon request, depending on the application requirements.

- Peeling Strength: Peeling strength (the resistance of the fabric layers separating) is also customizable to meet specific application needs.

- Denier and Threads per Inch:

- The fabric is available in multiple configurations based on the denier (the thickness of the polyester yarn) and the thread count per inch.

- Common configurations include 500D, 840D, 1000D, and 1500D, with thread counts ranging from 9×9 to 33×33, allowing users to choose the optimal balance between strength, flexibility, and weight.

Conclusion:

Hypalon-coated polyester fabric is a versatile and durable material that offers exceptional resistance to environmental conditions such as UV radiation, chemicals, and extreme temperatures. It is highly valued for applications in the marine industry, industrial equipment, and outdoor environments where durability and resistance to harsh conditions are critical. The customizable nature of the fabric, including its strength, elongation, and thickness, ensures it can be tailored to meet specific needs across a wide range of industries.

EAS Fiberglass Co., Ltd is a professional fiberglass products supplier and provides comprehensive and effective material industrial solutions covering the market of high-performance FRP, highly effective temperature insulation, and highly convenient construction. Nowadays, EAS owns various product lines of fiberglass yarn forming, woven fabrics, fabric coating/lamination, FRP, etc. The complete product lines enable EAS to master the quality control and products market competitive. Taking this advantage involves us in many projects and enhance brand promotion. Certified ISO9001-2008 equips EAS staff and management with a more professional operation. Certification of test reports for products is made by third-party laboratories SGS, TUV, DNV, etc.