PTFE-coated fiberglass fabric is a composite material made by coating fiberglass cloth with polytetrafluoroethylene (PTFE), a high-performance fluoropolymer. This combination results in a fabric that inherits the strength and durability of fiberglass along with the exceptional properties of PTFE.

Key Characteristics

-

High Temperature Resistance:

- PTFE-coated fiberglass fabric can typically withstand temperatures up to 500°F (260°C) and sometimes higher, making it suitable for high-heat applications.

-

Non-Stick Surface:

- The PTFE coating provides a smooth, non-stick surface, which is ideal for applications where materials should not adhere to the fabric.

-

Chemical Resistance:

- The PTFE layer is highly resistant to most chemicals, acids, bases, and solvents, ensuring durability in chemically harsh environments.

-

Low Friction:

- PTFE has a low coefficient of friction, which makes the fabric suitable for applications where sliding contact occurs.

-

Electrical Insulation:

- The fabric offers excellent electrical insulation properties, making it useful in electrical and electronic applications.

-

UV and Weather Resistance:

- PTFE-coated fiberglass fabric is resistant to UV radiation and weathering, suitable for outdoor applications.

-

Moisture Resistance:

- The material is impervious to water and moisture, providing long-term performance in humid or wet conditions.

Manufacturing Process

-

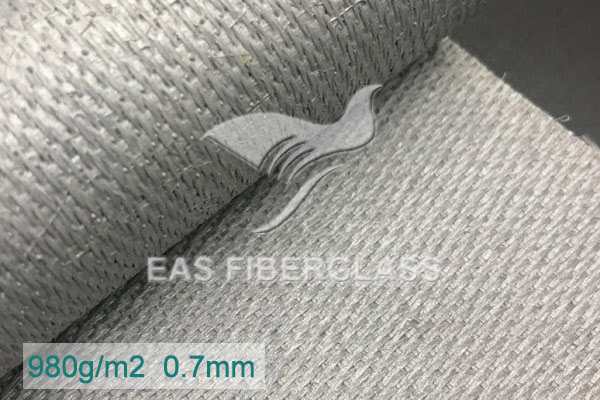

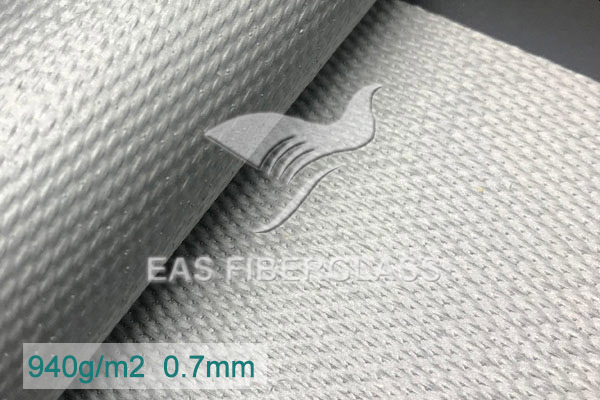

Fiberglass Cloth Production:

- Fiberglass yarns are woven into a cloth, providing a strong and flexible substrate.

-

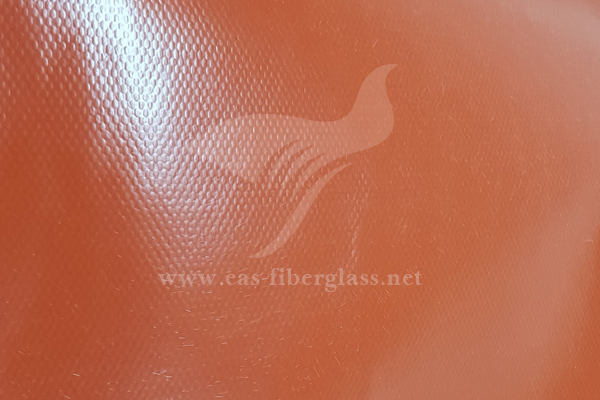

PTFE Coating:

- The fiberglass cloth is coated with PTFE, often through a dipping or lamination process, and then cured to bond the PTFE to the fiberglass.

Applications

-

Industrial Belting:

- Used in conveyor belts for high-temperature processes, such as in the food, packaging, and textile industries.

-

Heat Sealing and Release Liners:

- Employed in heat sealing machines where a non-stick surface is crucial.

-

Insulation:

- Utilized in thermal insulation blankets, jackets, and covers due to its heat resistance and insulating properties.

-

Electrical Insulation:

- Serves as an insulating material in electrical components and wiring.

-

Chemical Processing:

- Suitable for linings and covers in chemical processing plants due to its chemical inertness.

-

Architectural Membranes:

- Used in roofing and architectural structures where durability and weather resistance are essential.

Benefits

- Durability: The fiberglass core provides mechanical strength and durability, while the PTFE coating enhances its functional properties.

- Versatility: Suitable for a wide range of applications across various industries.

- Performance: Combines the best attributes of both materials, resulting in a high-performance fabric.

Considerations

- Cost: PTFE-coated fiberglass fabric is generally more expensive than other coated fabrics due to the high cost of PTFE.

- Handling: Requires specialized tools and techniques for cutting, sewing, and bonding due to the properties of PTFE.

Conclusion

PTFE-coated fiberglass fabric is a robust, high-performance material used in applications demanding high-temperature resistance, non-stick properties, and chemical inertness. Its unique combination of fiberglass and PTFE makes it suitable for demanding industrial and commercial uses.