Aerogel insulation blankets are innovative materials used for thermal insulation in various applications. Aerogels are incredibly lightweight and porous materials that consist of a network of interconnected nanoparticles. They are often considered one of the lightest solid materials available.

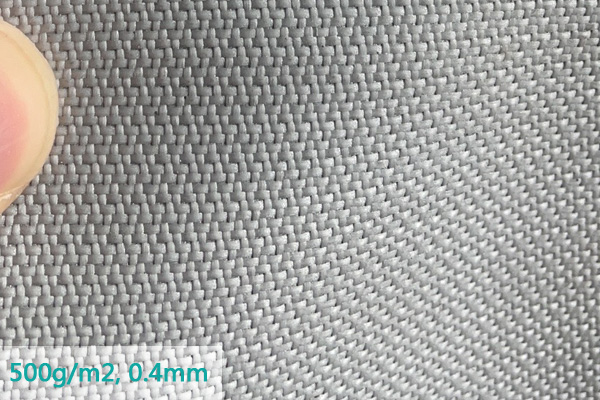

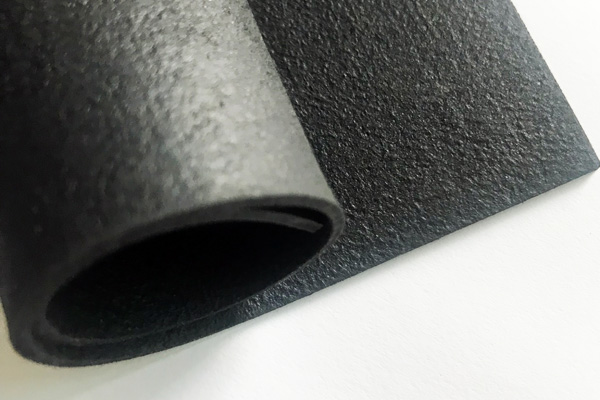

Aerogel insulation blankets are typically composed of aerogel particles dispersed within a flexible matrix, such as fiberglass or silica. This structure allows them to be flexible and easy to handle while retaining the exceptional insulating properties of aerogels.

Composition:

Aerogel insulation blankets typically consist of the following components:

-

Aerogel Particles: Aerogels are made up of a gel-like substance that undergoes a process called supercritical drying to remove the liquid component, leaving behind a solid with a highly porous structure. These aerogel particles are often composed of silica or other materials and have a very low density.

-

Flexible Matrix: The aerogel particles are dispersed within a flexible matrix material, such as fiberglass, polyester, or other polymers. This matrix provides structural support to the aerogel particles, allowing the blanket to maintain its shape and flexibility.

Properties:

Aerogel insulation blankets exhibit several key properties that make them highly desirable for thermal insulation:

-

Low Thermal Conductivity: Aerogels have extremely low thermal conductivity, typically in the range of 0.015 - 0.025 W/m·K. This property enables them to effectively reduce heat transfer by conduction, making them excellent insulators.

-

Lightweight: Aerogels are renowned for their lightweight nature. Despite their low density, they possess remarkable strength and structural integrity, making aerogel insulation blankets both lightweight and durable.

-

Flexibility: The flexible matrix material allows aerogel insulation blankets to conform to various shapes and surfaces, including irregular or curved structures. This flexibility makes them suitable for use in applications where rigid insulation materials may not be practical.

-

Hydrophobicity: Aerogels are inherently hydrophobic, meaning they repel water. This property prevents moisture absorption, which could otherwise compromise the insulation performance or lead to material degradation over time.

-

Chemical Resistance: Aerogels are chemically inert and resistant to most chemicals, acids, and bases. This resistance enhances their durability and suitability for use in harsh environments.

-

Wide Temperature Range: Aerogel insulation blankets can withstand a broad temperature range, from cryogenic temperatures (-200°C) to high temperatures (up to 650°C or more), depending on the specific formulation and application requirements.

Applications:

Aerogel insulation blankets find numerous applications across various industries:

Construction:

-

Building Insulation: Aerogel insulation blankets are used to insulate walls, roofs, and floors in residential, commercial, and industrial buildings. They help improve energy efficiency, maintain comfortable indoor temperatures, and reduce heating and cooling costs.

-

Pipelines: Aerogel blankets are wrapped around pipelines to provide thermal insulation and prevent heat loss during the transportation of hot fluids, such as steam, hot water, or oil. They also help protect pipelines from corrosion and environmental damage.

-

Refrigeration Units: Aerogel insulation blankets are used in refrigerators, freezers, and cold storage facilities to provide superior thermal insulation, maintaining low temperatures and reducing energy consumption.

Aerospace:

-

Spacecraft Insulation: Aerogel blankets are used in spacecraft insulation systems to protect against extreme temperature variations encountered in outer space. They provide thermal insulation for sensitive equipment, electronics, and spacecraft components.

-

Cryogenic Applications: Aerogel insulation blankets are employed in cryogenic systems, such as liquid hydrogen or oxygen storage tanks, to minimize heat transfer and maintain ultra-low temperatures required for cryogenic fluids.

Automotive:

-

Exhaust Insulation: Aerogel blankets are used to insulate exhaust systems in automobiles, trucks, and heavy-duty vehicles. They help reduce heat radiation from the exhaust pipes, improving vehicle performance and enhancing passenger comfort.

-

Battery Enclosures: In electric vehicles (EVs) and hybrid vehicles, aerogel insulation blankets are used to insulate battery enclosures, protecting the batteries from temperature fluctuations and extending their lifespan.

Oil & Gas:

-

LNG Storage Tanks: Aerogel insulation blankets are employed in liquefied natural gas (LNG) storage tanks to minimize heat ingress and maintain the low temperatures required for liquefaction. This helps prevent vaporization and maintains the integrity of the stored LNG.

-

Petrochemical Processing: In oil refineries and petrochemical plants, aerogel blankets are used to insulate equipment, vessels, and pipelines involved in high-temperature processes, such as distillation, cracking, and reforming.

Industrial:

-

High-Temperature Furnaces: Aerogel insulation blankets are utilized in industrial furnaces, kilns, and ovens to provide thermal insulation and reduce heat loss, improving energy efficiency and process control.

-

Cryogenic Storage: Aerogel blankets are used in cryogenic storage applications, such as cryogenic dewars and tanks, to minimize heat transfer and maintain the low temperatures required for storing cryogenic fluids like liquid nitrogen, oxygen, and argon.

These specific applications highlight the critical role that aerogel insulation blankets play in a wide range of industries, from construction and aerospace to automotive and oil & gas, by providing efficient thermal insulation solutions for diverse operational requirements.

EAS Fiberglass Co., Ltd is a professional fiberglass products supplier and provides comprehensive and effective material industrial solutions covering the market of high-performance FRP, highly effective temperature insulation, and highly convenient construction. Nowadays, EAS owns various product lines of fiberglass yarn forming, woven fabrics, fabric coating/lamination, FRP, etc. The complete product lines enable EAS to master the quality control and products market competitive. Taking this advantage involves us in many projects and enhance brand promotion. Certified ISO9001-2008 equips EAS staff and management with a more professional operation. Certification of test reports for products is made by third-party laboratories SGS, TUV, DNV, etc.